- Description

- Reviews

- FAQs

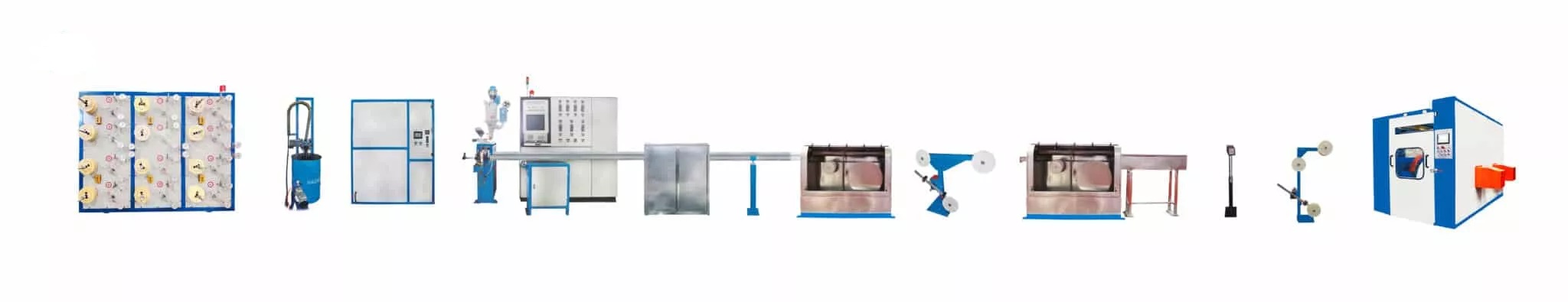

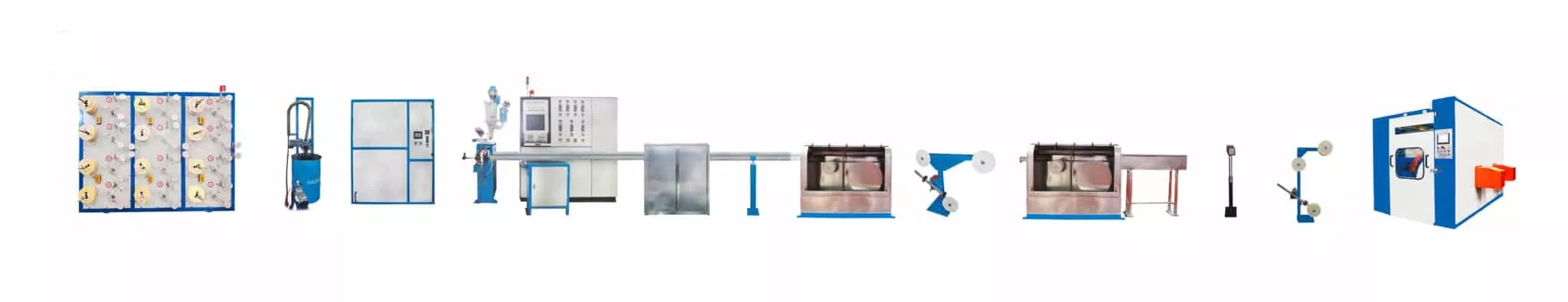

What Is ADSS Fiber Optic Cable Production Line

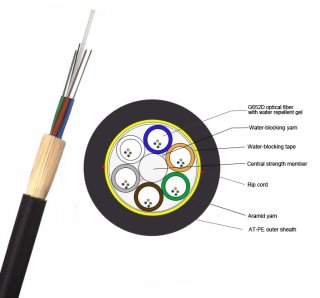

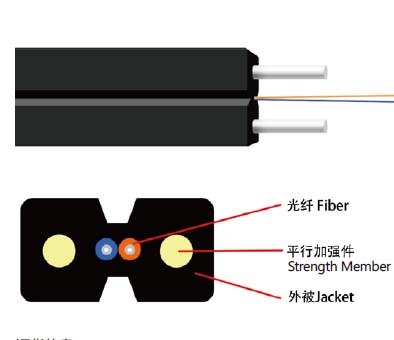

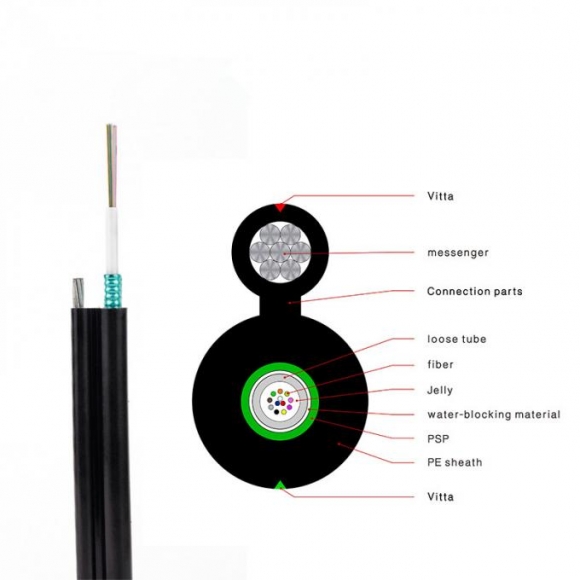

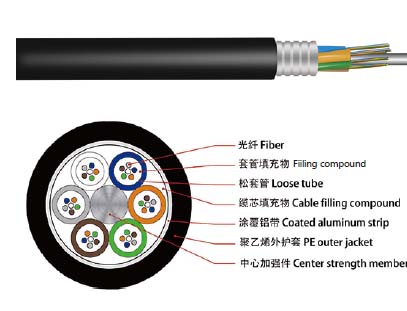

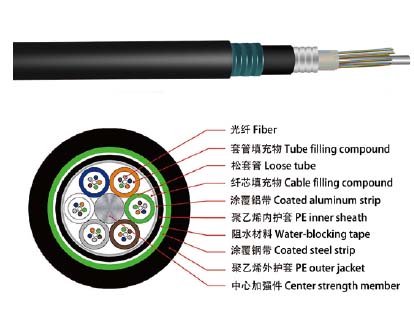

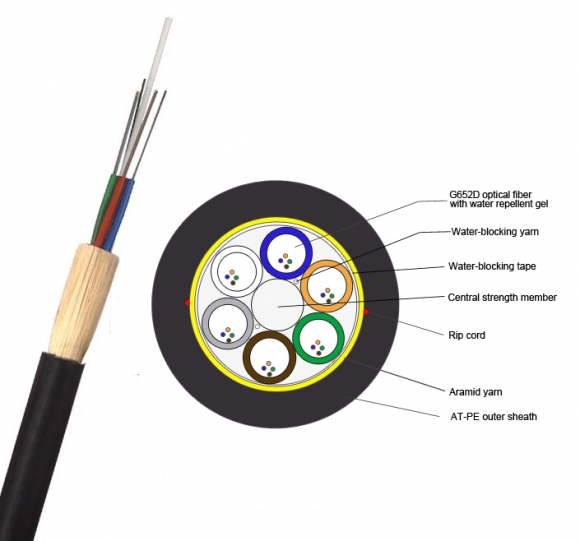

ADSS Fiber Optic Cable Production Line , All-dielectric self-supporting (ADSS) cable is a type of optical fiber cable that is strong enough to support itself between structures without using conductive metal elements. It is used by electrical utility companies as a communications medium, installed along existing overhead transmission lines and often sharing the same support structures as the electrical conductors.ADSS Cables. All-Dielectric Self Supporting Cables. The All-Dielectric Self Supporting (ADSS) Cable Is A Completely Non-Metallic Structure In Which The Tensile Load-Bearing Elements Are Integral Within The Circular Design Of The Cable – Usually In The Form Of Aramid Yarns Or Stranded Glass-Reinforced Plastic Rods.

ADSS is an alternative to OPGW and OPAC with lower installation cost. The cables are designed to be strong enough to allow lengths of up to 700 metres to be installed between support towers. ADSS cable is designed to be lightweight and small in diameter to reduce the load on tower structures due to cable weight, wind, and ice.In the design of the cable, the internal glass optical fibers are supported with little or no strain, to maintain low optical loss throughout the life of the cable. The cable is jacketed to prevent moisture from degrading the fibers. The jacket also protects the polymer strength elements from the effect of solar ultraviolet light.Using single-mode fibers and light wavelengths of either 1310 or 1550 nanometres, circuits up to 100 km long are possible without repeaters. A single cable can carry as many as 864 fibers.

ADSS Fiber Optic Cable Production Line is consists of three main parts

1- IPC+PLC CONTROL LOOSE TUBE ADSS FIBER OPTIC PRODUCTION LINE

- 1-12 Heads Fiber Pay Off: Put On 1-12 Cores Fiber By Danfoss Driver.

- Jelly Filling Machine: Fill The Jelly Into The Loose Tube And Remove The Air From It By Automatic.

- Electrostatic Removal Device: Remove Impurities From The Fiber Surface Before Extruder.

- Masterbatch Compounder: Fill The Color Masterbatch Of Another Color.

- Dryer And Automatic Hopper Machine: Will Hopper And Dryer The Raw Material By Automatic.

- Main Extruder: Using The Best Quality Screw From China, Extrusion The PP/PPT Material. And The Motor Using Siemens.

- Control Cabinet: PLC+IPC Control, More Easy Operation For The Worker, The Transducer Using American Emerson, Other Electric Parts Using Schneider.

- Warm And Cooling Water Trough: Cooling The Wire Down Slowly.

- Diameter Gauge: Display The Actual Diameter Of The Cable To The Operator.

- Capstan: Automatic Change The Line Speed By Panasonic Servo.

- Semi-Automatic Take Up: Motor Using Siemens, Transducer Using Emerson, The Control System By 7-Inch Kincotouch Screen Puls Siemens S7-200 PLC Control. It Will Change The Wire Coil By Automatic When One Pcs Is Full.

2-SZ LOOSE TUBE BUNCHED ADSS FIBER OPTIC PRODUCTION LINE

As SZ stranding defines the mechanical and environmental properties of your loose tube fiber optic cable, you need technology that you can rely on. Our SZ stranding technology is not only reliable, but it helps you produce flexible and durable cable for use in various applications.

SZ LOOSE TUBE BUNCHED ADSS FIBER OPTIC PRODUCTION LINE

SZ LOOSE TUBE BUNCHED ADSS FIBER OPTIC PRODUCTION LINE- Messenger Wire Pay Off: Put On The Messenger Wire

- Cylinder Dancer: Linkage With The Pay Off, Potentiometer + Cylinder Control

- Loose Tube Pay Off X 12 Sets: Put On The Loose Tube, The Max Cores Can Meet:12*12=144 Cores.

- Jelly Filling Machine: Fill The Jelly Before The Extruder Automatic.

- Dryer And Automatic Hopper Machine: Will Hopper And Dryer The Raw Material By Automatic.

- Control Cabinet: PLC+IPC Control, More Easy Operation For The Worker, The Transducer Using American Emerson, Other Electric Parts Using Schneider.

- SZ Stranding Device: The Control By Servo Motor And The Angle Can Be Adjustments From ±4π Unit ±20π.

- Double Heads Cross-Binder Machine: Cross Binding The Loose Tube By Servo Motor Plus Emerson Control.

- Single Head Cross-Binder Machine: Cores Binding The Loose Tube By Servo Motor Plus Emerson Control.

- Double Heads Wrapping Machine: Put On The Water Blocking Tape/Aluminum Foil/PET Film Etc.

- Diameter Gauge: Display The Actual Diameter Of The Cable To The Operator.

- 800mm Wheel Flat Belt Capstan Machine: The Power By Siemens Motor Plus Deceleration Box Plus Emersoncontrol.

- Cylinder Dancer: Linkage With The Take Up, Potentiometer + Cylinder Control

- 800-1600mm Gantry Type Take Up: Motor: Siemens, Drive: Emerson, Touch Screen: Siemens, PLC System: Siemens S7-1200

3-OPTICAL CABLE SHEATHING ADSS FIBER OPTIC PRODUCTION LINE

The sheathing process is where you apply the final touch to your loose tube fiber optic cable. Mechanical properties for different cable types are set with armoring and strength members. Our state-of-the-art extrusion technology offers you the ability to utilize a large variety of plastic materials to produce high-quality jacketing.

The sheathing normally contains the following components by option: Pay-off with tension dancer, yarn server, Steel tape pay-off, Jib crane, Steel tape Splice table & Welder, Metal tape accumulator, Steel tape corrugation and lubricator, Ripcord pay-off, Steel tape cone forming station, Armor powder application system for cone forming, Water blocking tape pay-off, Dual single head concentric binder, Mylar tape pay-off , Hot melt applicator,.90mm(or 120mm) Extrude, First Water trough, Second water trough, Diameter gauge/ lump detector, Spark tester, Hot stamp printer, Linear Belt Capstan, Cable accumulator, Take-up, Electrical control system (PLC)

ADSS OPTICAL CABLE SHEATHING PRODUCTION LINE

ADSS OPTICAL CABLE SHEATHING PRODUCTION LINE- 800-1600mm Gantry Type Pay Off: Motor: Siemens, Drive: Emerson, Touch Screen: Siemens, PLC System: Siemens S7-1200

- Cylinder Dancer: Linkage With The Pay Off, Potentiometer + Cylinder Control

- Messenger Wire Pay Off-1 Set: Put On The Messenger Wire.

- Armind Yarn Stranding Device* 2: 24-Heads Magnetic Damping Control

- Double Heads Steel Aluminum Tape Pay Off: Put On Steel-Aluminum.

- On-Line Seam Welding Device: Joint Weld Steel& Aluminum Tape When Changing One Tape Drum To Another.

- Metal Tape Corrugating Device: Corrugated The Steel Aluminum Before Extruder.

- Metal Tape Longitudinal Forming Device: Longitudinal Forming And Fixed Diameter Before The Extruder

- Aramid Yarn Pay Off: Twist The Aramid Yarn With The Loose Tube After Aluminum. The Tension Control By Each’ Magnetic Damping.

- Dryer And Automatic Hopper Machine: Will Hopper And Dryer The Raw Material By Automatic.

- Main Extruder: Using The Best Quality Screw From China, Extrusion The PE/PVC Material. And The Motor Using Siemens.

- Control Cabinet: PLC+IPC Control, More Easy Operation For The Worker, The Transducer Using American Emerson, Other Electric Parts Using Schneider.

- Warm And Cooling Water Trough: Cooling The Wire Down Slowly.

- Diameter Gauge: Display The Actual Diameter Of The Cable To The Operator.

- Capstan:Power: 7.5KW Siemensmotor + Deceleration Box + 7.5KW American Emersontransducer + Speed-Governor.

- Power Frequency Spark Machine: Online Test For Outer Sheathing Breakage.

- Cylinder Dancer: Linkage With The Take Up, Potentiometer + Cylinder Control

- 800-1600mm Gantry Type Take Up: Motor: Siemens, Drive: Emerson, Touch Screen: Siemens, PLC System: Siemens S7-1200

What Is ADSS Fiber Optic Cable

- Customers Reviews

* Delivery Time.

We need 1-2 days to process your order before shipping. There are two shipping methoed.

Fast Delivery: The delivery time for US, European countries the delivery will take 3-5 days.

Slow Delivery: The delivery time for US, European countries the delivery will take 7-15 days.

* Tracking information.

After we ship package, customer receive automatic email with tracking details.

* Lost Package Policy.

If a package did not arrive in 2 weeks after the shipping date, then this package is treated as Lost. In this case a new package will be shipped to the customer provided we are able to give the same items as those purchased by the customer. If we are not able to provide the same items to substitute the lost ones we will either propose to the customer similar items or refund their cost as it will be mutually agree with the customer. If one or more items neither the same nor similar are available to be shipped, the customer can request to cancel the order entirely, thus the total cost of the order including shipping and handling cost will be fully refunded.

Recently Viewed

- ADSS Fiber Optic Cable Production Line

- US$210,000.00

(0)

(0) (0)

(0) (0)

(0) (0)

(0) (0)

(0)